In order to fulfill a continuing demand for student housing, and enable the school to proceed with critical academic projects, Stanford University chose Clark Pacific to help in the construction of new housing units. Precast concrete modules manufactured by Clark Pacific created new graduate student housing in Escondido Village. Four residence buildings provide 436 beds and related on-campus amenities, helping to alleviate the demand for additional graduate housing on campus.

The precast concrete components helped expedite the construction process when compared to other building methods, allowing for student occupancy in the Fall Quarter of 2014.

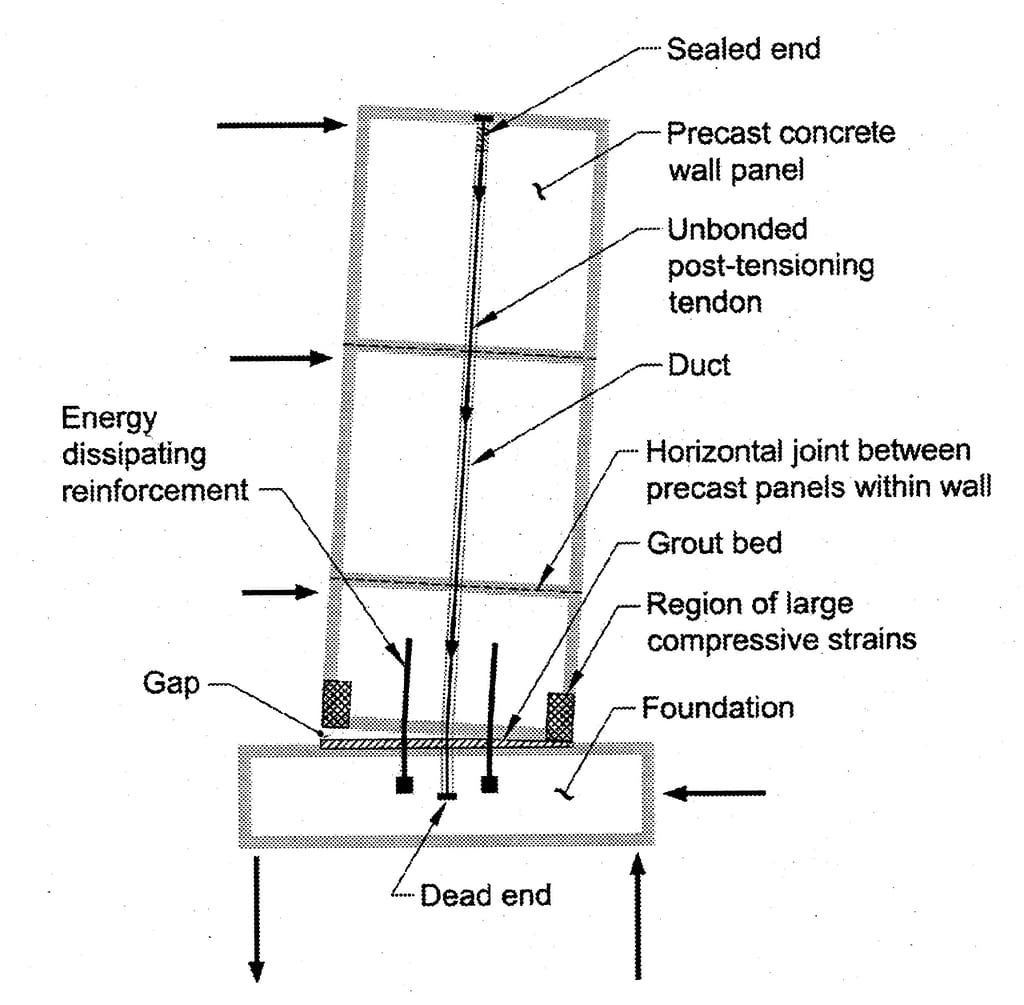

PRECAST ROCKING WALLS

The structural system for the residence halls, which also formed the architectural skin and demising walls of the building, was constructed using vertically post-tensioned, precast concrete rocking wall panels. This system was developed as part of the multi-year PCI sponsored PRESSS research project, and after years of transition from research to practice, could now be designed in accordance with the 2010 California Building Code.

The walls were designed to rock at their base, with special energy dissipating rebar developed into the foundation and debonded up into the wall panel. Vertical post tensioning was installed through the middle of each rocking wall panel, anchored with a loop into the foundation. Rebar to be coupled into the wall panel and sleeves for the vertical post tensioning (ACI ITG.jpg). The student housing complex was the first real, practical application of the precast concrete vertically post tensioned shear wall technology in the San Francisco Bay Area.