Infinite options.

Infinite possibilities.

Clark Pacific is a manufacturer of Infinite Facade™, a single source prefabricated building envelope solution that simplifies the building envelope design.

Infinite benefits.

Sustainable

High performance

Manufactured offsite

Integrated scope

Design flexibility

Reduced risk

Product highlights

- Accelerated schedule

- Aesthetically flexible system

- Lightweight

- Factory-installed windows and insulation

- Manufactured offsite

- Drywall options

- Single point of contact for the facade warranty

Infinite options.

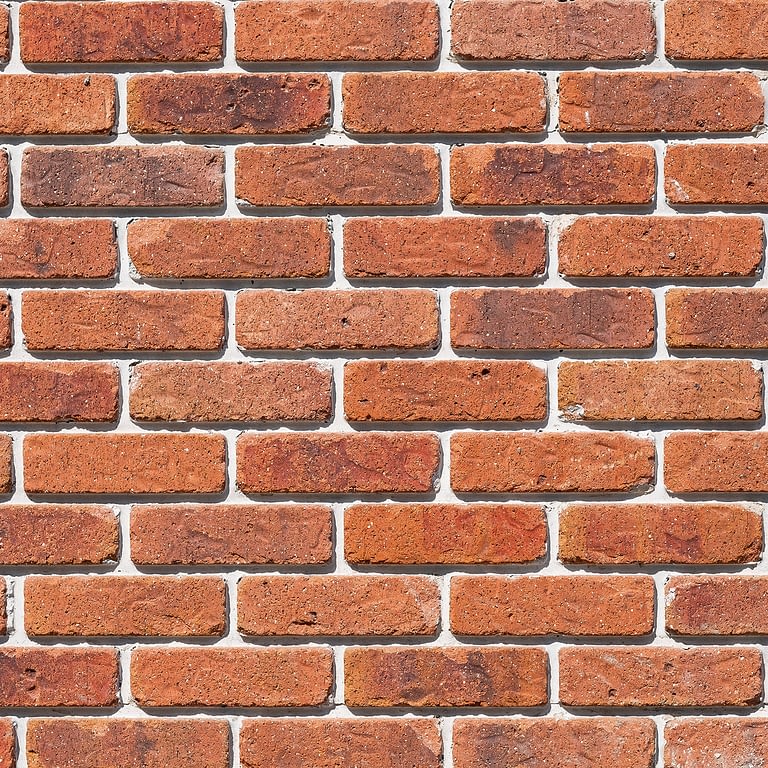

In addition to the wide variety of colors and textures available, other material can be cast into the exterior veneer- such as brick, terracotta and stone. The use of form liners also allows for an endless number of geometric pattern and reveals to be incorporated into the design.

Heavy Sandblast & Polished

Infinitely responsible.

- Reduces heating energy by ~30%, compared to typical construction assemblies

- Global warming potential (GWP) reduced by over 60%, compared to traditional curtain wall systems.

- Reduced cement mix by 35% and supplemented with cementous materials – reducing GWP overall by 20%

Infinite savings.

Using our advanced energy analysis tool, discover the potential energy savings with Infinite Facade. Our user-friendly tool determines the potential reduction in Energy Use Intensity (EUI), the percentage of annual energy savings, and the associated costs based on your project’s specific details, including geographical location.

Effortlessly compare various Infinite Facade window to wall options to compare energy savings and identify the most efficient solution for your needs.

Start exploring now and unlock the energy-saving potential of Infinite Facade.

Infinite solutions.

To best meet window and daylighting needs use one or all three configurations on the project to achieve the design intent.

Infinite Facade 75

Infinite Facade 75, the most cost-effective system, which utilizes punched window openings surrounded by your choice of opaque finishes.

Infinite Facade 85

Infinite Facade 85 allows punched openings to align with the top of the panel and minimizes the occurrence of horizontal joints. It allows for approximately 6″ of increased vision from the interior, increasing the total window height.

Infinite Facade 100

Infinite Facade 100 eliminates sealant joints at the floor line and provides full height, continuous exterior glass, and can accommodate more translucent glass from the interior. This configuration can utilize the Infinite Facade 75 or 85 frame and connection configuration to maximize the extra vision from the interior.

Facades Consortium Group LLC is a partnership between Wells and Clark Pacific to facilitate and accelerate the R&D efforts surrounding Infinite Facade, a single-source prefabricated building envelope system, simplifying facade design. Both companies are aligned in the vision to evolve the lightweight panel systems that help create a resilient, durable, and sustainable built environment. We are committed to designing, manufacturing, and installing a quality product no matter where the project is located. Infinite Facade is engineered to be flexible to meet regional building and design requirements.